I

Introduced in 1996 by The Armoloy® Corporation, the 98Rc XADC-Armoloy® coating offers today’s industrial design and engineering community the opportunity to expand their options to enhance the performance of their equipment and tooling. The addition of nano-diamond spheres to the Armoloy® TDC coating technology is unique, but still allows for cost effectiveness and rapid delivery to ensure in-budget and on-time delivery.

The XADC-Armoloy® coating enhances the durability of components used in wide range of applications from plastic injection mold tooling to coating aerospace applications that require long life expectancy, extreme wear protection, low frictional characteristics and corrosion protection.

Absolute Adhesion

XADC-Armoloy® will not fracture from the basis metal unless the metal substrate itself fractures or fatigues. The absolute, positive adhesion that is created with the special application of XADC-Armoloy® is a major benefit to its users. XADC-Armoloy® compiles to the standard ASTM B 489-85 bend test without chipping, cracking or separating from the basis metal.

Applied at temperatures under 200 degrees F (100°C) there are absolutely NO changes in the basis metals that the XADC-Armoloy® coating is applied to. Like Armoloy® TDC, XADC-Armoloy® will adhere and perform well on all major ferrous and nonferrous basis metals. Aluminum. magnesium and titanium are not considered good substrates for coating with Armoloy® processes.

Comparative Hardness

Functional Temperature Ranges

XADC-Armoloy® withstands temperatures from -400°F to 1400°F (-240°C to 775°C). At temperatures above 1200°F, XADC-Armoloy® will react with materials such as carbon monoxide, sulfur vapor and phosphorus. Temperatures above 1800°F are not recommended.

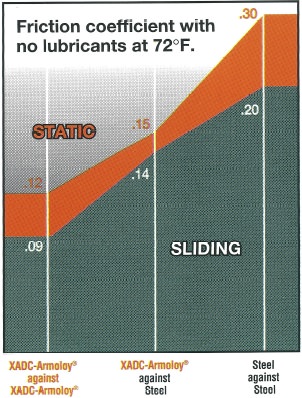

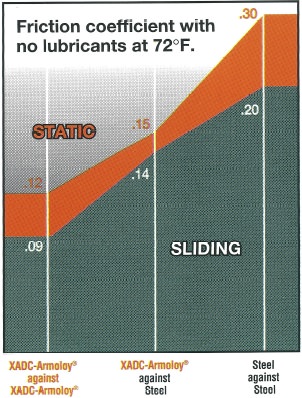

Friction Reduced with XADC-Armoloy®

XADC-Armoloy®reduces friction to a greater degree than other coatings in today’s marketplace.

Testing indicates the inherent lubricity of XADC-Armoloy® may reduce the need for lubrication, providing a cleaner and more environmentally friendly workplace.

Galling conditions may be eliminated with XADC-Armoloy®, which effectively allows XADC-Armoloy® coated parts to operate against other XADC-Armoloy® coated parts.

Corrosion Resistance

Tests have shown that XADC-Armoloy® provides corrosion resistance exceeding 440C stainless steel. Basis material coated with XADC-Armoloy® exceeds performance levels of non-coated materials multiple times.

XADC-Armoloy®reduces friction to a greater degree than other coatings in today’s marketplace.

Testing indicates the inherent lubricity of XADC-Armoloy® may reduce the need for lubrication, providing a cleaner and more environmentally friendly workplace.

Galling conditions may be eliminated with XADC-Armoloy®, which effectively allows XADC-Armoloy® coated parts to operate against other XADC-Armoloy® coated parts.

XADC-Armoloy®reduces friction to a greater degree than other coatings in today’s marketplace.

Testing indicates the inherent lubricity of XADC-Armoloy® may reduce the need for lubrication, providing a cleaner and more environmentally friendly workplace.

Galling conditions may be eliminated with XADC-Armoloy®, which effectively allows XADC-Armoloy® coated parts to operate against other XADC-Armoloy® coated parts.